1. 金属陶瓷(CERMET)材质定义

1. Definition of metal ceramic (CERMET) material

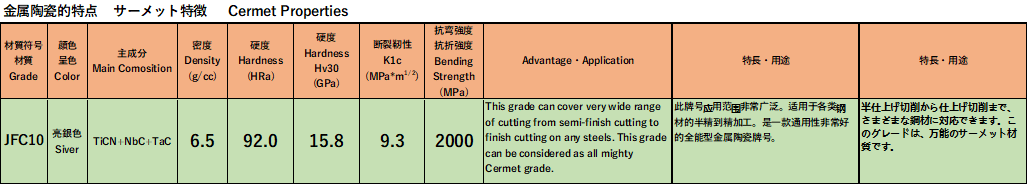

金属陶瓷(CERMET)是 “陶瓷(CERAMIC)” 与 “金属(METAL)” 的复合术语。其硬质成分与传统硬质合金(WC 系)存在本质区别,以钛(Ti)系碳化物、氮化物或碳氮化物为核心成分,属于硬质材料范畴,亦被行业称为 “Ti 系硬质合金”。

Metal-ceramics (CERMET) is a composite term for "ceramics (CERAMIC)" and "metals (METAL)". Its hard component is fundamentally different from traditional hard alloys (WC series), with titanium (Ti) based carbides, nitrides, or carbonitrides as core components, falling under the category of hard materials, and is also referred to in the industry as "Ti based hard alloys."

2. 公司产品核心特性

2. Core features of the company's products

公司开发的碳氮化钛基金属陶瓷切削工具,拥有卓越的抗崩损性与耐磨损性能,可广泛应用于钢材的粗加工至精加工全流程。该产品凭借高水准的加工表面质量、长效使用寿命及优良耐熔着性,能够助力客户公司优化钢材加工工艺的合理性、显著提升生产效率。

The titanium carbonitride-based metal ceramic cutting tools developed by the company have excellent chipping resistance and wear resistance, and can be widely used in the entire process from rough machining to finishing of steel. This product, with high-quality machining surface finish, long service life, and excellent resistance to welding, can help clients optimize the rationality of the steel processing technology and significantly improve production efficiency.

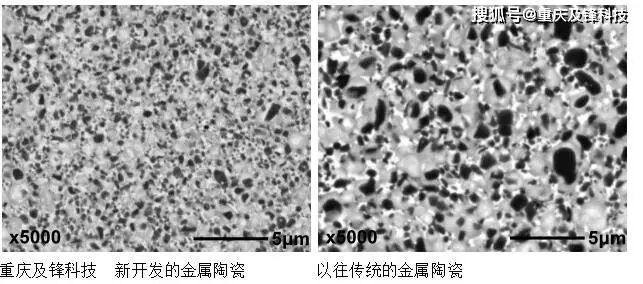

3. 产品晶粒特性对比(附晶粒图片)

3. Comparison of product grain characteristics (with grain images)

相较于传统金属陶瓷产品相比,晶粒更加超微粒子化,提高了抗崩损性及耐磨损性。

金属陶瓷粘合相(钴、镍)的碳氮化钛固溶粒子间隙变小,抑制切削时粘合相软化,实现提高耐熔着性与优异的完成面品质。

超微粒子硬质粘合相的高强度化与高熔点粘合相的大压缩应力效果,使抗崩损性得以提高。

Compared to traditional metal ceramic products, the grains are more ultrafine, enhancing resistance to chipping and wear resistance.

The gaps between the titanium carbonitride solid solution particles in the metal ceramic bonding phase (cobalt, nickel) decrease, suppressing the softening of the bonding phase during cutting, which improves wear resistance and achieves superior surface quality.

The high strength of the ultrafine hard bonding phase and the high compressive stress effects of the high melting point bonding phase enhance resistance to chipping.

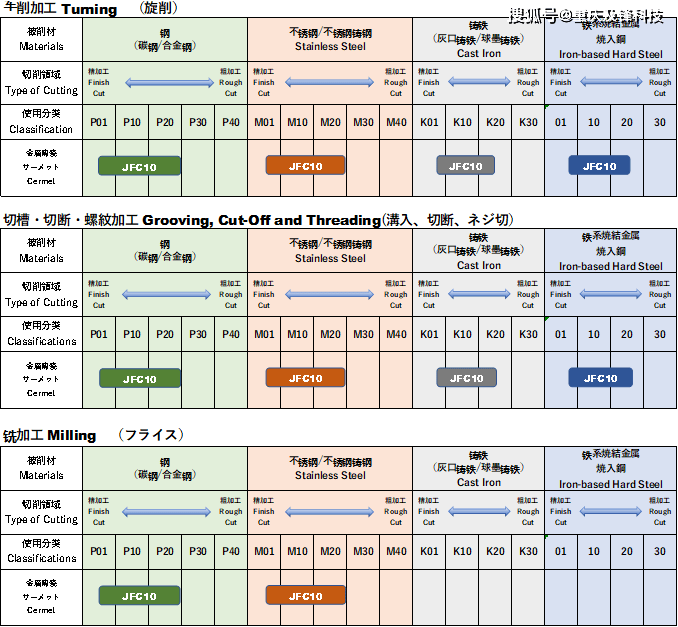

4. 产品适用与供应说明

4. Product applicability and supply description

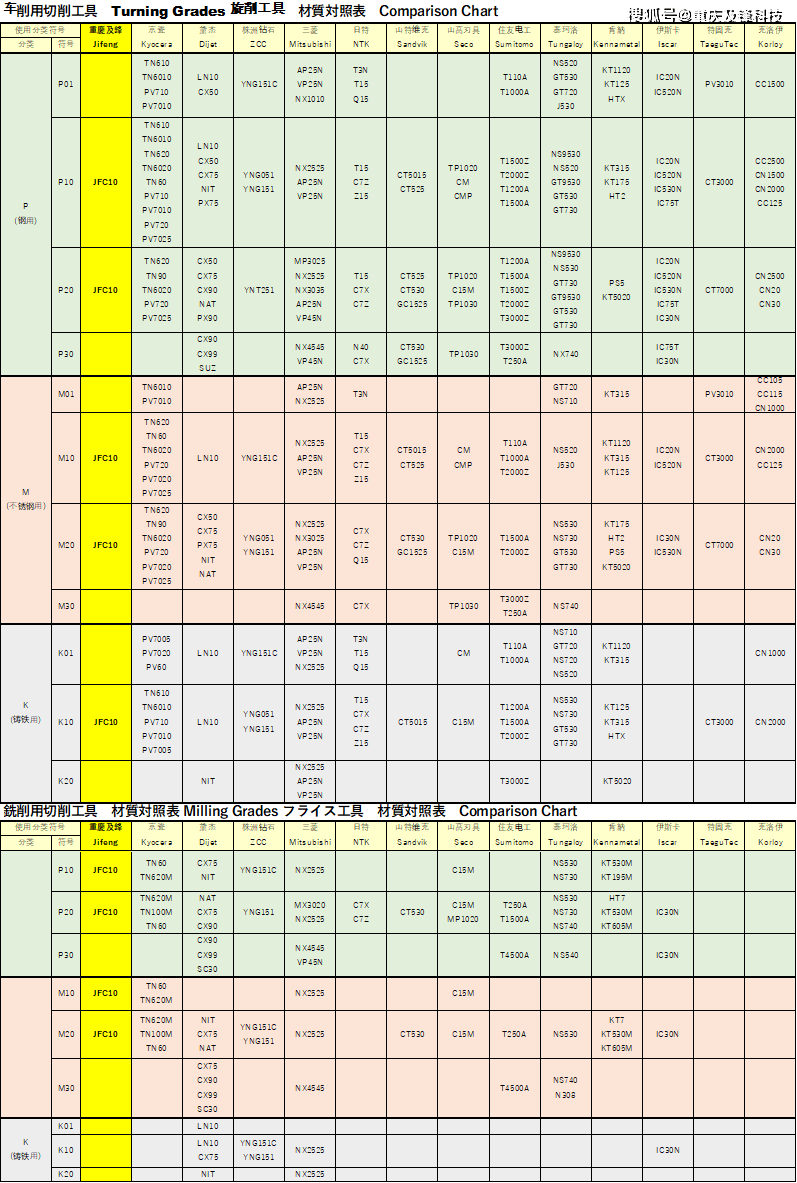

(1)适用范围

(1) Scope of Application

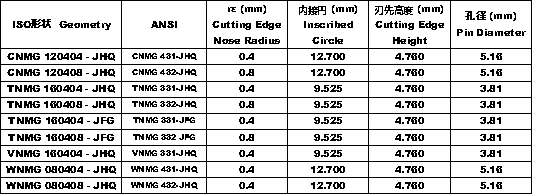

(2)现阶段可提供产品形状

(2) Currently available product shapes

今后随时根据客户的意见及市场情况调整产品

今后随时根据客户的意见及市场情况调整产品

未来,公司将持续依据客户反馈意见及市场需求变化,动态调整产品规格、品类及性能参数,致力于为客户提供更贴合实际加工需求的解决方案。

In the future, the company will continue to dynamically adjust product specifications, categories, and performance parameters based on customer feedback and changes in market demand, striving to provide solutions that better meet actual processing needs.

长按识别二维码关注公众号,点击下方菜单栏左侧“微信群”,申请加入交流群。