UL于4月20日宣布,将推出用于增材制造业的新型塑料鉴定标准(“蓝卡标准”)。这项计划专门针对 3D 打印材料,可认为是 UL 现有塑料认证标准(黄卡标准)的延伸计划。

与传统制造(如注射成型)不同,3D打印过程引入了可变性,会因样本如何被打印,而对产品属性和性能产生显著影响。增材制造的塑料计划定义了识别用于3D打印和3D印刷组件及产品塑料所需的额外要求。

蓝卡计划证明某材料适用于特定的3D打印技术,并有助于确保零组件或终端产品制造商使用经过测试的材料,且该材料的生产也将由独立测试实验室定期监控。

“UL一直通过为增材制造人力开发、设备安全与设备合规性提供解决方案来满足客户需求。”UL研发经理Thomas Fabian博士说:“将蓝卡计划添加到我们的性能材料产品中,展现了UL致力于帮助客户成功应对增材制造领域层层挑战的承诺。”

UL认证的3D打印材料将会添加到UL iQTM 塑料和PROSPECTOR®数据库中。这有助于有意销售其材料是通过UL认证,并可用于 3D 印刷组件材料的塑料制造商,也有助于想要认证 3D 印刷零组件的制造商。此外,蓝卡计划还可满足有兴趣在其设备中使用 3D 印刷零件和组件的终端产品制造商。

The UL Blue Card for Additive Manufacturing

Plastics for Additive Manufacturing

The incredibly fast-growing 3D printing, or Additive Manufacturing (AM) industry, is challenging plastics manufacturers to consider how this technology will impact their market, operations and products. Unlike traditional manufacturing such as injection molding, the 3D printing process introduces a variability which significantly impacts material properties based on how test specimens are printed.

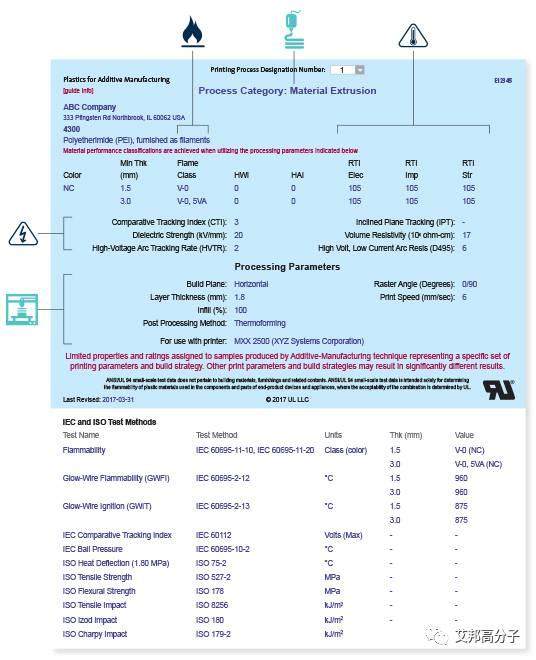

The Plastics for Additive Manufacturing Program (Blue Card Program) is a UL service that enables customers to have published data that facilitates pre-selection of 3D printed materials and components for use in various end products. It defines the requirements necessary to recognize plastics intended for 3D printing, proving the safety, integrity and usefulness of materials.

The UL Blue Card helps ensure that the component or end-product manufacturer is using a tested and certified material, as well as being monitored at regular intervals by an independent test laboratory.

When to use the UL Blue Card Program

The Blue Card Program is to be applied when the material has been processed using one of the following 3D printing technologies:

Material Extrusion

Powder Bed Fusion Systems

VAT Polymerization

Material Jetting

Binder Jetting

Sheet Lamination

Direct Energy Deposition

The Blue Card also includes:

information about the 3D print technology used to process the material;

the 3D printer model designation;

test specimen build parameters specific to the technology (e.g. build plane, raster angle, air gap, etc. for material extrusion technology) and,

multiple safety and performance-related property ratings tested to appropriate standards.

Blue Card vs Yellow Card: The Blue Card differs from the Plastics Recognition Program (Yellow Card Program) in that the Blue Card publishes plastics materials and components intended for 3D printing while the Yellow Card is typically applied for traditional manufacturing technologies such as blow molding, extrusion, film blowing, injection molding rotation molding and vacuum forming.

IMPORTANT NOTE: None of the performance properties/ratings from a UL recognized material (Yellow Card) can be applied, when that material is used in a 3D printing process to print a 3D part.

How to get a UL Blue Card

A Blue Card is automatically issued when a material intended for 3D printing receives a UL Recognized Component Mark. Certified materials are added to the UL iQTM and UL’s Prospector® databases.

Benefits of the UL Blue Card

The UL Blue Card benefits:

Material manufacturers producing materials for use in 3D printed components

Component manufacturers interested in using tested and certified materials to be able to offer certified 3D printed components

End-product manufacturers interested in using tested and certified 3D printed parts and components in their applications

As Material And Component Manufacturers: Since certified materials are added to the UL iQTM and UL’s Prospector® databases, your Blue Cards are immediately visible to thousands of designers, engineers, and suppliers searching for a material or component provider who meets certain safety and performance requirements.

As End-Product Manufacturers: Save time and money in the process of seeking certification for end products or systems by using the UL Certified plastics. UL certified plastics are also covered under UL’s Follow-Up Services – a product’s ongoing certification assessment that helps ensure that products continue to meet UL standards of safety and performance.

Boost Product Discoverability – Extend your UL Blue Card with a White Card

Manufacturers can add value by increasing coverage to include the performance properties customers are looking for – all backed up with third-party verification. The White Card, an extension at the bottom of a Blue Card (and Yellow Card), allows manufacturers to promote their product‘s performance credentials to the global markets. It relates to international standards, while the information on the Blue or Yellow Card is typically relevant to North America.

消息来源: UL

第五届TPE/TPV技术与应用研讨会

(6月23日• 苏州 )

5th TPE / TPV Technology and Application Forum

(June 23, 2017,Suzhou, China)

主办方:艾邦高分子

Organizer: Aibang Polymer

规模:300人

Size: 300

时间:6月23日 星期五

Time: Friday, June 23, 2017

地点:苏州 福朋喜来登酒店

Location: Suzhou, China

主题:TPV新材料、新应用、新设备、新工艺

Main Topics: New Materials/ Applications/ Equipment/ Technology on TPV

会议议题(暂定)/Meeting topic (to be confirmed):

1.TPV过去、现在、未来 (拟邀请 北京化工大学 张立群教授/ 北化弹性体 田明教授)

1. TPV past, present and future

2.TPV全球市场发展状况以及趋势( IHS 徐徐)

2. TPV global market development and trends

3.EPDM在TPV中的应用(中石化三井 技术总监 王建国)

3. Application of EPDM in TPV

4.TPV 在汽车门封中应用介绍(山东道恩高分子材料股份有限公司 陈文泉 技术总监)

4. TPV in the car door seal application introduction

5.TPV 吹塑制品在汽车中的应用(安徽中鼎橡塑制品有限公司 任福海经理)

5. TPV blow molding products in the application of the car

6.TPV在汽车内外饰领域应用(待定)

6. TPV in the automotive interior and exterior applications

7.TPV在其他领域应用(拟邀请 国内外知名 TPV企业)

7. TPV in other areas of application

8.过氧化物在PP/EPDM动态硫化中的应用(阿科玛 阴景贤)

8. Application of Peroxides in PP / EPDM Dynamic Vulcanization

9.酚醛硫化树脂在TPV动态硫化中的应用 (拟邀请:圣莱科特化工 亚太技术经理 李道力)

9.Application of Phenolic Resin in Dynamic Vulcanization of TPV

10.TPV挤出共混工艺(拟邀请:克劳斯马菲等)

10. TPV extrusion blending process

11.汽车密封条TPV与传统材料之争及趋势(天津天逸合成精密机械有限公司 滕智全总经理)

11.Competition between TPV and traditional materials in automotive sealing strip

12.TPV制品挤出工艺

12. TPV product extrusion process

13.TPV制品其他成型工艺

13. TPV products other molding process

14.TPV其他相关助剂(除味剂,交联剂等)

14. TPV other related additives (in addition to taste agents, crosslinking agents, etc.)

赞助及支持单位:

圣莱科特化工(上海)有限公司

山东道恩高分子材料股份有限公司

上海中石化三井弹性体有限公司

安徽中鼎橡塑制品有限公司

安徽雄亚塑胶科技有限公司

天津天逸合成精密机械有限公司

苏州瑞高新材料有限公司

阿科玛

IHS

报名方式:

张小姐: 18320838592; 微信同电话号码。长按以下二维码即可报名

方式1:请加微信并发名片报名;

方式2:请加微信并回复:姓名+公司+职位+手机+邮箱+主营产品

方式3:在线登记报名;阅读原文进入在线报名;

方式4:请编辑“姓名+公司+职位+手机+邮箱+主营产品”发短信到张小姐18320838592 ;

注意:每位参会者均需要提供信息;

点击阅读原文,在线报名

始发于微信公众号:艾邦高分子